I-RIM Working Group on Robotics 4.0

Working Group Topics

Industry 4.0

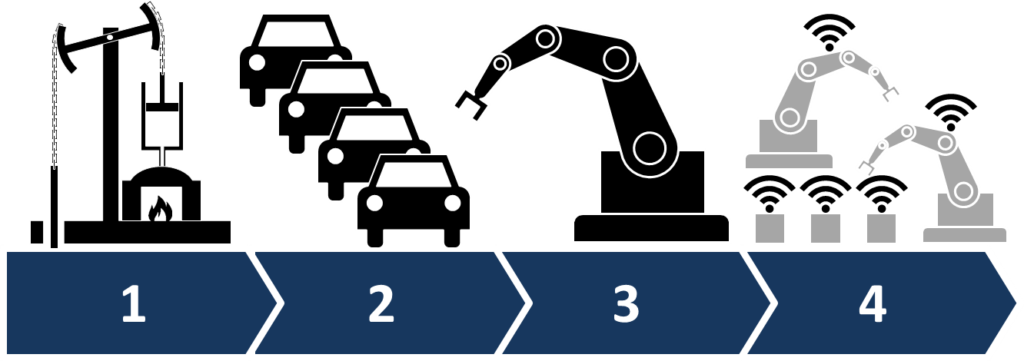

After the steam pump, the assembly line and the PC, which were all catalysts for the previous industrial revolutions, robotics and automation are recognized among the main enabling technologies of Industry 4.0 since they:

- improve productivity;

- improve quality (reducing human errors);

- reduce cost;

- meet customers’ expectation.

Robotics 4.0

In industrial and emerging applications, e.g., agriculture 4.0 and healthcare 4.0, the focus of robotics is gradually shifting from motorization (robotics 1.0), to automation (robotics 2.0), digitalization (robotics 3.0), and lately to collaboration and cognition (robotics 4.0).

In robotics 4.0, the robotic system is characterized by being cloud-based, having human-robot natural interactions and being distributed.

Going Beyond

- The fifth industrial revolution will be focused on co-operation between man and machine with an extreme level of customization.

- From traditional automation to cognitive automation (the operator, with augmented functionalities, becomes a factor of increased productivity for the factory)

- Collaborative automation (human-machine collaboration)

- Machine/Robot supervision activities

- Machine/Robot support activities

- towards industry 5.0 (collaborative industry, humans augmented thanks to cobot integration and connectivity)

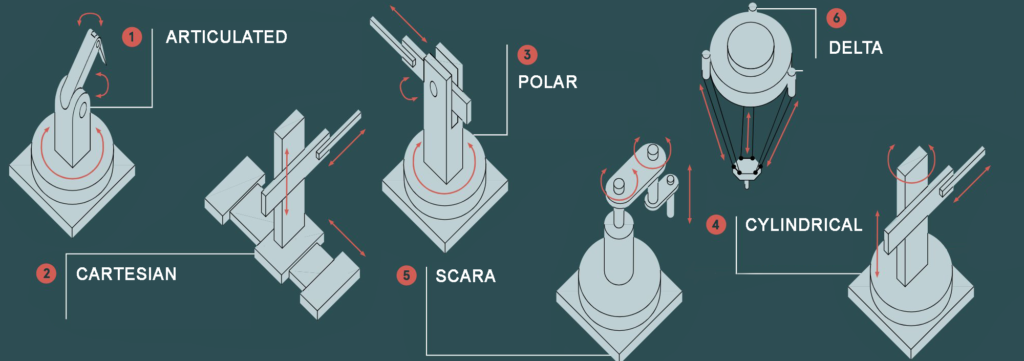

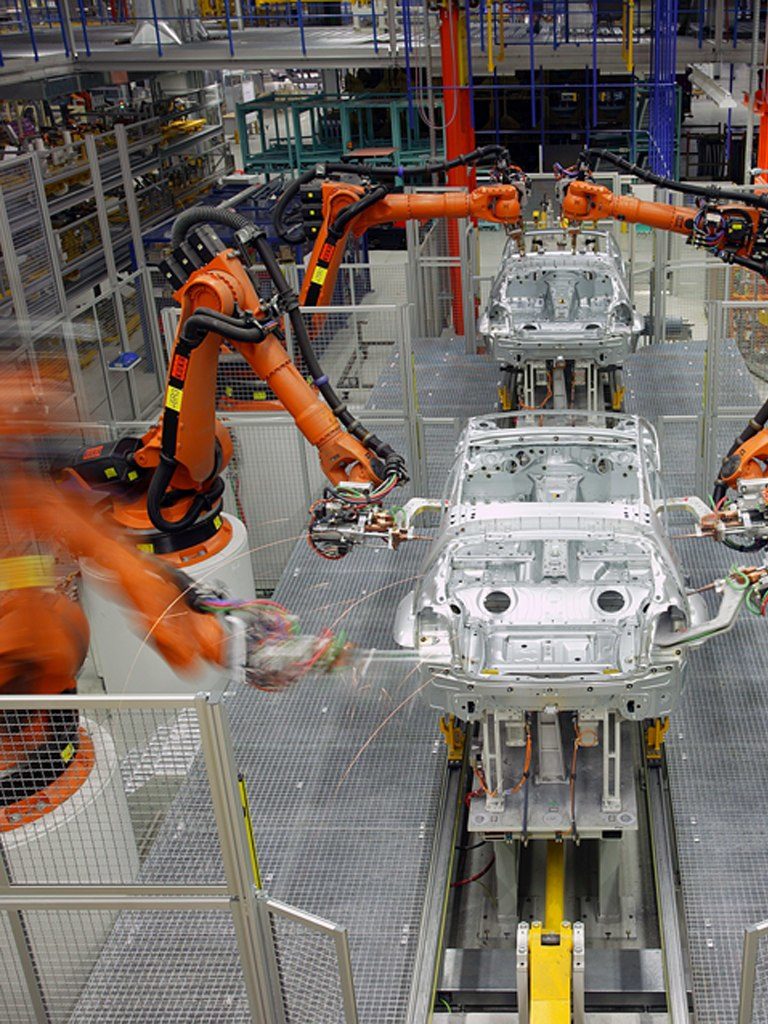

Industrial & Service Robots in Production Processes

The basis of the fourth industrial revolution are industrial robots and service robots that are very flexible in order to perform any activity. Moreover, they significantly increase productivity and make independent decisions. The main applications are:

- Accurate assembly processes

- Material handling

- Machine tending

- Material removal

- Welding

- Quality inspection

Digital Twin for Industrial Robotics

A virtual, dynamic model in the digital world that is fully consistent with its corresponding physical entity in the real world and can simulate its physical counterpart’s characteristics, behavior, life, and performance in a timely fashion (Zhuang et al., 2018). The main applications are:

- Software-in-the-loop (SIL) and Hardware-in-the-loop (HWIL) simulation

- Virtual real-time simulation using Virtual and Augmented Reality (VR, AR)

- PHM (prognostics and health management)

Autosys Industrial Solutions, CC BY-SA 4.0, via Wikimedia Commons

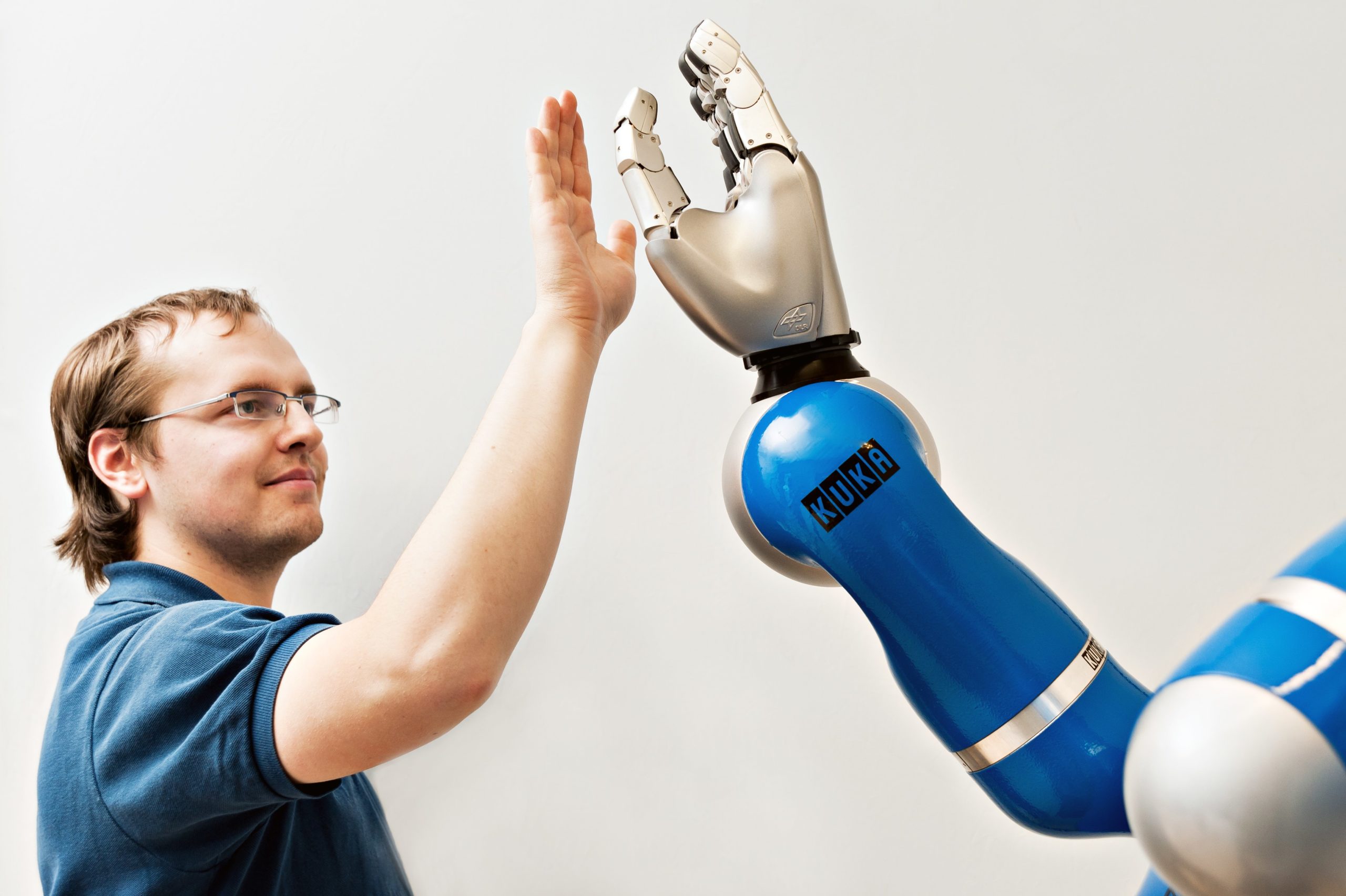

Human Robot Collaboration in Manufacturing

Robots that co-exist in the same environment together with humans, without neglecting safety nor efficiency, in contrast to traditional robots that predominantly work independently from humans and often reside in a cage. The main applications are:

- Accurate assembly processes

- Material handling

- Machine tending

- Material removal

- Welding

- Quality inspection

Robotics for Logistics 4.0

Significant improvement in terms of times and efforts can be achieved in warehouses with the introduction of robotics in the phases of mobilisation of goods and orders preparations. The main applications are:

- Mobile robots (Autonomous guided vehicles – AGV and laser guided vehicles –LGV, drones) in logistic scenarios

- Robotic solutions for the storage, distribution and sales of goods

- Automatic palettizer

Emiliano García-Page Sánchez, CC BY-SA 2.0, via Wikimedia Commons

I-RIM Working Group on Robotics 4.0

Research Community

Chair

Prof. Engr. Mariagrazia Dotoli

Full professor in Automation

Coordinator of Ph.D. Program in Industry 4.0 – Doctorate School

Dept. of Electrical and Information Engineering (DEI),

Polytechnic of Bari, Bari, IT

email: ti.ab1751319545ilop@1751319545iloto1751319545d.aiz1751319545argai1751319545ram1751319545

Co-Chair

Prof. Engr. Antonio Frisoli

Full professor of Engineering Mechanics and Robotics

Head of Human-Robot Interaction Area – Chief Scientific Officer @ Wearable Robotics

Scuola Superiore Sant’Anna, Pisa, IT

email: ti.as1751319545ipann1751319545atnas1751319545@ilos1751319545irf.o1751319545inotn1751319545a1751319545

Research community

Collaborative Robots

- Profs. Mariagrazia DOTOLI and Raffaele CARLI – Polytechnic of Bari

- Profs. Antonio FRISOLI and Calogero Maria ODDO – Sant’Anna School of Advanced Studies

- Profs. Paolo ROCCO and Andrea ZANCHETTIN – Polytechnic of Milan

- Prof. Marco CARRICATO – University of Bologna

- Prof. Andrea CHERUBINI – Montpellier University

Smart Manufacturing

- Prof. Andrea MATTA – Polytechnic of Milan

- Prof. Cesare FANTUZZI – University of Modena and Reggio Emilia

AI for Manufacturing Systems

- Profs. Paolo FIORINI Diego DALL’ALBA and Daniele MELI – University of Verona

- Drs. Vito RENÒ and Nicola PEDROCCHI – STIIMA CNR

- Dr. Andrea ORLANDINI – ISTC CNR

Human-robot Interaction

- Prof. Cristian SECCHI – University of Modena and Reggio Emilia

- Profs. Riccardo MURADORE and Andrea CALANCA – University of Verona

- Prof. Alessandro DE LUCA – University of Rome La Sapienza

- Prof. Arash AJOUDANI – IIT

- Prof. Andrea CHERUBINI – Montpellier University

- Dr. Andrea ORLANDINI – ISTC CNR

Modeling and Control of Manipulators

- Prof. Manuel BESCHI – University of Brescia

Industrial Robotics

- Prof. Sauro LONGHI and Massimo CALLEGARI – Polytechnic University of Marche

- Profs. Francesco BASILE and Pasquale CHIACCHIO – University of Salerno

- Prof. Bruno SICILIANO – University of Naples Federico II

I-RIM Working Group on Robotics 4.0

Plans and Contacts

- Mapping the community

- Engaging new members

- Organizing special sessions / workshops at scientific conferences

- Organizing special issues in scientific journals

- Supporting / organizing international conferences

- Organizing technical seminars /events to discuss challenges and solutions

- Creating a mailing list for communications

- Building a webpage to collect information about the WG

Keep updated on our latest events and news!

[Form id=”6″]